Elite Sports (Huizhou) Co., LTD

Tel: +86 752 3277280

Mobile: +86 188 1674 6741

Skype: elitesportshk

What's App: 86-18816746741

E-mail: sales@elitesportshk.com

Website: www.elitesportshk.com

Quality control for all our products and components above everything and we believe “Quality above everything”, for which, we continue to invest the best resource on quality improving, including the investment in processing and inspection facilities, R&D department, and management means. Our target is zero defects with products.

Our QC system is structured to consider individual customer requirements for part complexity relative to overall part quality. Our goal is to assure that all deliverable products, both in-house manufactured or purchased, meets specifications.

PRE-PRODUCTION INSPECTION

The purpose of this inspection process is to inspect and identify the different materials to be used prior to the initial production sequence to ensure that all the materials to be used are free from any damages or defects prior to official assembly. Should there be any flaws on the raw materials to be used, items will be considered "DEFECTIVE" and will be thrown away.

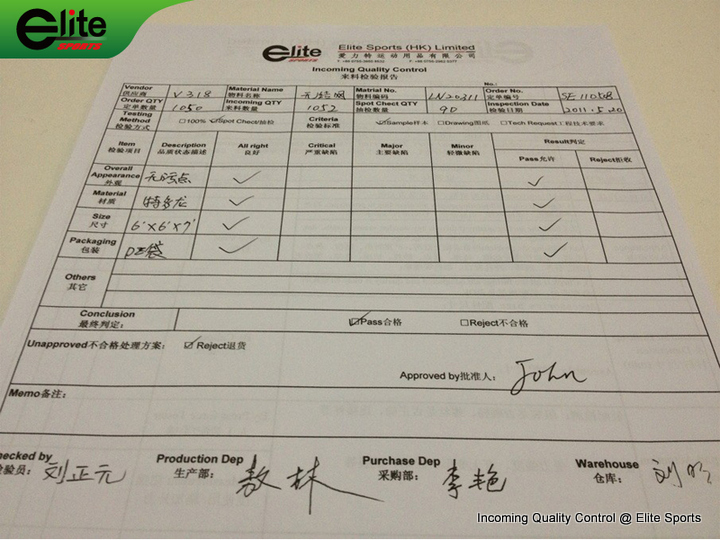

MATERIALS INSPECTION

The purpose of this inspection process is to inspect and verfify that the different raw materials are categorized according to its proper item specification to ensure that all of the products are on the same category prior to the initial assembly. Items that have missing pairs will be labeled as "INCOMPLETE" and will be returned to phase one for recalibration of parts.

ASSEMBLY INSPECTION

The purpose of this inspection prcess is to verify that all the products that came out of the production queue are properly assembled and are still in place to ensure that no items were duplicated during the production process. Should there be any items that came out defective during the production queue; the assembly inspection will help filter all the production anomalies.

VISUAL INSPECTION

The purpose of this inspection process is to examine and verify that all of the items being inspected are free from any post-assembly wear and tear, damages, defects and other production anomalies to ensure that the items are ready for the next inspection process. Should there be any items that are found to be damaged, these products will be labeled as "DEFECTIVE" and will be placed on its appropriate queue.

WEIGHT AND MEASUREMENT INSPECTION

The purpose of this inspection process is to thoroughly measure the right diameters and sizes of the items being inspected to ensure that all of the items are in uniform size.

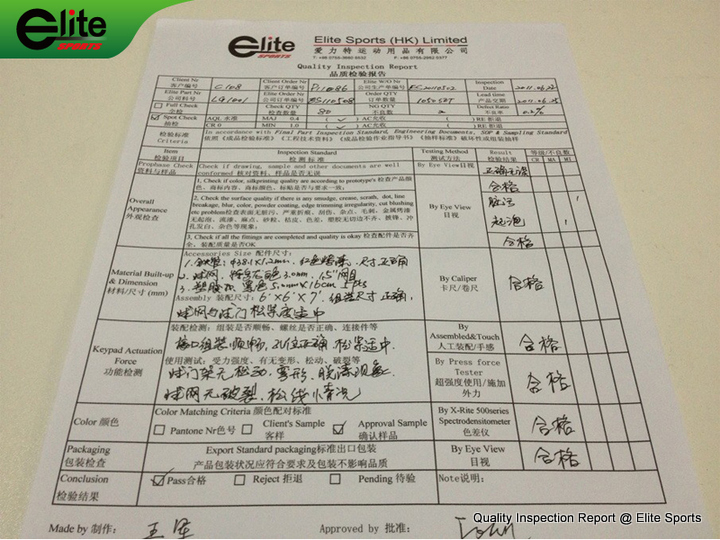

FINAL INSPECTION

The purpose of this inspection process is to verify that all the products, regardless of value, have passed the series of tests to detemine the overall quality of products being inspected.

In a word, We're checking the quality on behalf of you, and care of you.